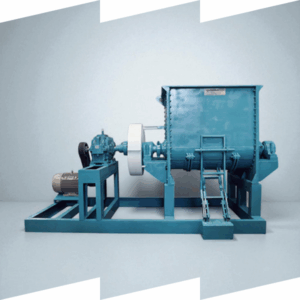

Advanced Detergent Soap Plant for Efficient Soap and Cake Production

RAMESHWAR STEEL FAB is one of India’s premier Detergent Soap Plant Manufacturers with effective and well-designed detergent-manufacturing solutions. Our Detergent Soap Plants are so designed that they blend raw material, perfume, and dyes as per prescribed formulation to achieve comparable quality and performance. Through the use of advanced technology machinery for mixing, extruding, cutting, and molding, we automate every step of the production of detergent cakes in a bid to achieve maximum production and minimal time lost.

With our different models of design availability, our soap detergent plants are built with quality material. Designing them upon requirement-specificity is also feasible. You would need small setup or large setup automation; RAMESHWAR STEEL FAB provides you with robust, power-saving, and export-standard machinery to facilitate consistent progress and continuous development for the world’s manufacturers and soap-making industry in India.

The plant is generally applied in detergent producing plants, industries, and chemical plants to make washing soaps, laundry bars, and multi proposed cleaning cakes. The plant can accommodate both the small and large scale operations and hence high productivity, low manpower needs and low maintenance.

Uses of a Detergent Soap Plant

Production of cleaning soaps and industrial detergent formulations.

- Stainless steel contact parts ensure hygiene and corrosion resistance.

- User friendly design for easy operation and cleaning.

- High output capacity with low power consumption.

- Modular construction allows flexible installation.

- Equipped with vacuum plodding system for uniform texture and finish.

Detergent manufacturing units.

Being a prominent Detergent Soap Plant Exporter, we deliver world-class soap manufacturing equipment designed with precision engineering and international quality standards. Our plants are built to perform efficiently under diverse climatic and operational conditions, making them ideal for global detergent manufacturers.

We export complete soap production systems equipped with sigma mixers, duplex vacuum plodders, and cutting & stamping units. These machines are designed to ensure consistent bar density, smooth texture, and precise shape. Each export consignment undergoes rigorous testing to guarantee durability and performance.

Being a prominent Detergent Soap Plant Exporter, we deliver world-class soap manufacturing equipment designed with precision engineering and international quality standards. Our plants are built to perform efficiently under diverse climatic and operational conditions, making them ideal for global detergent manufacturers.

We export complete soap production systems equipped with sigma mixers, duplex vacuum plodders, and cutting & stamping units. These machines are designed to ensure consistent bar density, smooth texture, and precise shape. Each export consignment undergoes rigorous testing to guarantee durability and performance.

Being a prominent Detergent Soap Plant Exporter, we deliver world-class soap manufacturing equipment designed with precision engineering and international quality standards. Our plants are built to perform efficiently under diverse climatic and operational conditions, making them ideal for global detergent manufacturers.

We export complete soap production systems equipped with sigma mixers, duplex vacuum plodders, and cutting & stamping units. These machines are designed to ensure consistent bar density, smooth texture, and precise shape. Each export consignment undergoes rigorous testing to guarantee durability and performance.