High-Quality Bar Soap Making Plant Manufacturer

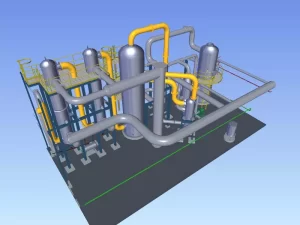

A Bar Soap Making Plant is an in-house manufacturing plan that aims at producing high quality toilet, bath, beauty bars, medicated, and laundry bars soaps. The plant comprises of superior machinery that is designed to deal with mixing of soaps, refining, plodding, cutting, stamping, cooling and packaging with precision and consistency.

The Bar Soap Making Plant uses saponified soap noodles, fatty acids, additives, perfumes, moisturizers, as well as colorants. The latter are introduced into the mixer and refined using triple roll mills or duplex plodders and extruded into continuous soap bars. The soap bar receives its final size and shape as well as branding impression by the cutting and stamping machines.

The plant is constructed using strong construction and stainless-steel contact parts which provides hygiene, safety and long term performance. The plant can be scaled to a scale of small scale to full automatic production lines that are high speed, depending on the manufacturing requirements.

The Bar Soap Making Plant can be used with personal care companies, cosmetic industries, laundry soap manufacturers, and other personal label brands interested in making soaps that have a consistent hardness, aroma, foam quality and appearance.

Bar Soap Making Machinery

Bar Soap Making Machinery: It is a type of specialized equipment that is used to convert raw noodles of soap or saponified mass into a finished soap bar. The equipment is capable of refining, combining, controlling moisture, and shaping bars of soap perfectly.

The machinery typically includes:

These machines are engineered using heavy duty steel, wear resistant components, and advanced control systems to support continuous 24×7 production. They help maintain perfect soap consistency, smooth surface finishing, accurate weight, and attractive appearance critical for branding and market value.

Whether for small scale soap startups or large industrial factories, these machines ensure efficiency, hygiene, reduced manual labor, and maximum production output.

Bar Soap Making Full Line Machinery

Bar Soap Making Full Line Machinery refers to an end to end integrated line of machines that transform raw materials into fully finished, packed soap bars. This complete production system is ideal for manufacturers requiring consistent quality, high-speed output, and reduced production costs.

A typical full line includes:

Raw Material Conveyor / Feeding System

Duplex Vacuum Plodder

Soap Mixer (Sigma or Ribbon type)

Bar Cutting Machine (Automatic / Manual)

Triple Roll Mill / Refining Unit

Soap Stamping & Branding Machine

Cooling & Hardening Conveyors

Packing Machine (Flow Wrap / Shrink Wrap)

The full production line is designed to ensure efficiency, proper blending, fine texture, air-free extrusion, and perfect finishing. Automation can be customized depending on production needs—from 100 kg/hour to over 5 tons/hour.

This full line machinery is especially beneficial for companies producing branded soaps, private-label soaps, herbal soaps, beauty soaps, and hotel soaps. With user-friendly operation and minimal maintenance, the machinery guarantees long-term performance and quick return on investment.