Leading Fully Automatic Soap Making Plant Exporter in Togo

We are a reliable Fully Automatic Soap Making Plant Exporter In Togo with the best production systems that can facilitate the production of high quality bathing soaps, toilet soaps, laundry soaps, and multipurpose wash bars. Our entire automatic line is designed to be precise, high capacity, and continuously running in its operation and thus the best choice when it comes to the contemporary soap industries which aim at achieving maximum output and uniformity in the quality of its products.

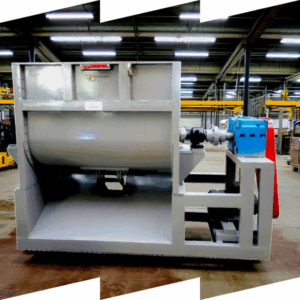

The plant consists of the required machinery, including sigma mixers, refining plodders, duplex vacuum plodders, stamping machinery, bar cutters, conveyors, drying machinery and automated packing equipment. These elements combined form a whole end-to-end solution to making soaps with the right texture, weight, good hardness and quality finishing.

Caustic soda, fragrances, colors, essential oils, additives, preservatives, and moisturizers are raw materials that are processed in a very precise manner to produce soaps of the type that meets both domestic and export level standards. All machines are of a robust design and made of chemical resistant materials and low maintenance parts that make them reliable in operation in all the key industrial areas in Togo such as Kara, Bassar, Mango, Dapaong, Tchamba, Niamtougou, Bafilo, Vogan, Badou, and Biankouri.

We are also providing the full service of exports which includes preparation of plant layout, installation of machinery, commissioning, staff training and long term technical services. The fully automatic plants of our soap making assist the soap industry of Togo to enhance the production capacity, minimise cost of operations, reduce dependency on man power, and the quality of their product remains the same to supply the market through reliability and excellence to the increasing demand.

Uses

Continuous soap manufacturing with minimal manual intervention

Export-oriented soap production for domestic and international markets

Features

- Fully automated operation reducing labor requirements

- High-speed refining and plodding technology

- Durable, corrosion-resistant machinery build

- Consistent cutting, stamping, and bar finishing

- Low energy consumption and high productivity

- Low maintenance design with long machine life

- High production capacity with energy-efficient performance

- Low manpower requirement reducing operational cost